ISO 8 cleanrooms are moderately controlled environments designed to maintain acceptable levels of airborne particulate contamination. They are widely used in industries such as pharmaceuticals, biotechnology, medical device manufacturing, and electronics assembly. While ISO 8 cleanrooms do not require the ultra-low particle concentrations of ISO Class 5 or Class 7 cleanrooms, proper airflow and filtration systems are critical to maintaining a controlled environment and ensuring product quality, safety, and regulatory compliance.

Maintaining proper airflow and filtration in an ISO 8 cleanroom requires a combination of effective HVAC design, strategically placed filtration units, and controlled air distribution. These systems work together to remove contaminants, maintain positive pressure, and ensure that particle concentrations remain within ISO standards. For organizations planning or operating ISO 8 facilities, detailed guidance on system design, operational practices, and monitoring protocols can be found in resources such as the ISO 8 Clean Room Requirements.

Airflow Design Principles

Airflow design in ISO 8 cleanrooms plays a vital role in controlling particle levels. Unlike higher-class cleanrooms, ISO 8 environments often use turbulent airflow or a combination of turbulent and partially unidirectional airflow systems. The goal is to dilute and remove airborne particles generated by personnel, equipment, or material handling.

The cleanroom layout and equipment placement must complement the airflow system. Furniture, workstations, and machinery should not obstruct airflow or create dead zones where contaminants can accumulate. Air distribution must ensure uniform airflow throughout the space, including high-traffic areas and critical work zones. Correctly designed airflow reduces the risk of contamination and helps maintain particle counts within ISO limits.

Filtration Systems

Filtration is a fundamental component of any ISO 8 cleanroom. High-efficiency particulate air (HEPA) filters are typically used to remove the majority of airborne particles. While ISO 8 cleanrooms have less stringent filtration requirements compared to ISO Class 5 cleanrooms, the filters still need to effectively capture particles that could compromise product quality or process integrity.

Filter placement is crucial to achieving optimal air quality. Ceiling-mounted HEPA filters are common, providing even air distribution across the cleanroom. Filtered air flows into the room and displaces contaminated air toward return vents, ensuring continuous particle removal. Regular maintenance and testing of filters, including integrity checks and replacement schedules, are essential to maintain effective filtration performance.

Air Change Rates

The air change rate, measured as the number of air exchanges per hour, is an important consideration in ISO 8 cleanroom design. Proper air change rates help dilute airborne contaminants and prevent particle accumulation. ISO 8 cleanrooms generally have lower air change rates than stricter cleanrooms, but they still require sufficient turnover to maintain the desired cleanliness level.

Calculating the correct air change rate depends on factors such as cleanroom size, occupancy, equipment density, and process requirements. Higher-traffic areas may require increased air changes to compensate for particle generation from personnel and materials. Ensuring adequate air changes also supports environmental stability by reducing temperature and humidity fluctuations.

Pressure Control

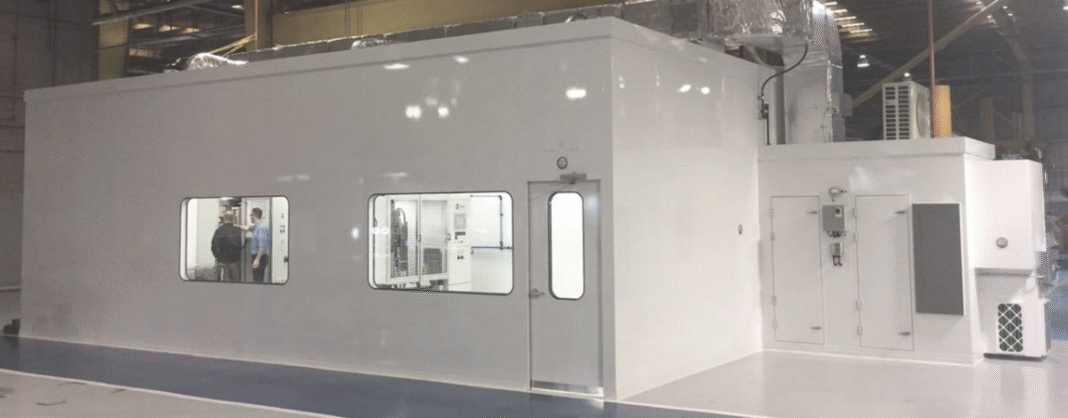

Maintaining positive pressure in an ISO 8 cleanroom is essential to prevent the ingress of contaminated air from adjacent areas. Pressure differentials between clean zones and surrounding spaces are achieved through controlled airflow and proper sealing of doors, windows, and pass-throughs. Even slight leaks can compromise particle control, so pressure monitoring and adjustment systems are important to maintain compliance with ISO standards.

Airlocks and gowning rooms contribute to pressure control by acting as buffer zones between the cleanroom and less controlled areas. Properly designed entry and exit procedures minimize disruptions to airflow and maintain the integrity of the clean environment.

Environmental Monitoring

Monitoring airflow, filtration performance, and particle concentrations is critical for ISO 8 cleanrooms. Particle counters and airflow sensors provide real-time data to ensure that systems are operating correctly. Continuous monitoring allows for early detection of deviations from standards, enabling corrective actions before contamination impacts processes or products.

Periodic testing, including “at-rest” and “in-operation” measurements, is conducted to verify compliance with ISO standards. “At-rest” testing assesses cleanroom conditions without personnel present, while “in-operation” testing evaluates the environment during normal operational activities.

Maintenance and Cleaning

Routine cleaning and maintenance are integral to effective airflow and filtration performance. Floors, walls, ceilings, and work surfaces must be cleaned regularly using low-lint materials and approved disinfectants. HVAC systems, filters, and vents require scheduled inspections and preventive maintenance to prevent degradation in performance and maintain compliance with ISO standards.

Conclusion

Proper airflow and filtration are essential to maintaining the controlled environment of an ISO 8 cleanroom. By implementing effective HVAC systems, strategically placed HEPA filters, adequate air change rates, positive pressure, and environmental monitoring, organizations can ensure particle concentrations remain within ISO limits. Regular maintenance and cleaning further support system performance and compliance. Understanding and adhering to airflow and filtration requirements is key to sustaining ISO 8 cleanroom standards, protecting products, and achieving reliable and efficient operations across a range of industries.