Accurate pH measurement is essential in laboratories, industrial processes, and environmental monitoring. However, over time, pH sensors can experience sensor drift, which affects the reliability of readings and can lead to incorrect data interpretation. Understanding the causes, effects, and mitigation strategies for sensor drift is critical for maintaining accurate and consistent pH measurements.

Understanding Sensor Drift in pH Measurement

Sensor drift refers to the gradual deviation of a pH sensor’s readings from the true value over time. This can occur due to changes in the glass membrane, reference electrode deterioration, or contamination of the sensor components. Drift can affect both laboratory and industrial pH sensors, compromising the accuracy of experiments, quality control processes, or environmental monitoring programs. Modern pH sensors are designed to minimize drift, but regular maintenance and calibration are essential to maintain optimal performance.

Causes of Sensor Drift

Several factors contribute to sensor drift in pH measurement:

- Aging of Electrode Components – Over time, the glass membrane and reference electrode gradually lose sensitivity, leading to slow deviations in readings.

- Contamination – Deposits from the sample or environmental particles can interfere with electrode function, altering the measured pH.

- Temperature Fluctuations – Repeated exposure to varying temperatures can affect electrode response and accelerate drift.

- Electrolyte Depletion – In reference electrodes, the internal electrolyte can become depleted, reducing the stability of the potential.

- Harsh Chemical Exposure – Strong acids, bases, or aggressive solvents can damage sensor components, increasing drift rates.

Effects of Drift on Measurement Accuracy

Sensor drift can lead to inaccurate pH readings, affecting decisions in research, industrial processes, and environmental monitoring. In laboratories, drift may produce unreliable experimental data, compromising reproducibility and scientific conclusions. In industrial applications, incorrect pH readings can result in improper chemical dosing, process inefficiencies, or even equipment damage. Environmental monitoring may be affected by inaccurate assessment of water or soil conditions, potentially leading to flawed analysis and regulatory non-compliance.

Detecting Sensor Drift

Recognizing sensor drift early is essential to maintain measurement reliability. Signs of drift include gradual changes in readings despite stable sample conditions, frequent recalibration requirements, or inconsistent results between sensors. Regular comparison with standard buffer solutions can help identify drift and indicate when maintenance or replacement is necessary.

Mitigating Sensor Drift

Proper maintenance, calibration, and storage practices are key to minimizing sensor drift:

- Regular Calibration – Calibrating sensors with standard buffer solutions before and during use corrects for gradual shifts in readings.

- Proper Storage – Keeping the electrode hydrated in an appropriate storage solution preserves the glass membrane and reference electrode.

- Cleaning and Maintenance – Removing deposits and contaminants from the sensor ensures stable readings and prolongs sensor life.

- Using Quality Sensors – High-quality sensors with robust materials and stable reference systems are less prone to drift.

- Environmental Control – Minimizing exposure to extreme temperatures and harsh chemicals reduces the risk of accelerated drift.

Reducing Operational Impact

In applications where continuous monitoring is required, such as industrial process control or environmental monitoring, drift can be managed through frequent calibration, redundant sensors, or automated correction systems. Some modern pH sensors include self-diagnostic features that alert users when drift exceeds acceptable thresholds, enabling proactive maintenance.

Choosing the Right Sensor to Minimize Drift

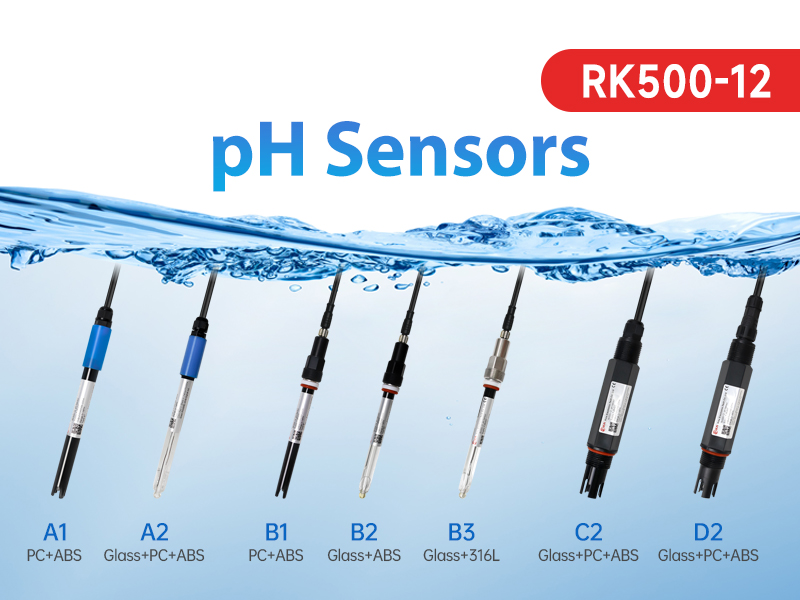

Selecting a sensor suited for the specific application environment can significantly reduce drift. Sensors designed for harsh chemical environments, high temperatures, or long-term immersion generally experience lower rates of drift. Additionally, digital sensors with onboard compensation and advanced reference designs provide more stable readings over extended periods.

Conclusion

Sensor drift is an inevitable phenomenon that affects the accuracy and reliability of pH measurements. Understanding its causes, monitoring for early signs, and implementing proper maintenance and calibration practices are essential to mitigate its impact. By selecting appropriate sensors and following best practices, users can ensure accurate, consistent pH measurements, supporting reliable research, efficient industrial operations, and effective environmental monitoring.