As urban infrastructure continues to expand, the importance of efficient and reliable sewer inspection technologies has never been greater. Maintaining underground pipelines is a complex task that requires precision, durability, and advanced diagnostic capabilities. In response to these challenges, sewer camera manufacturers worldwide have focused on innovation to meet the evolving needs of municipalities, contractors, and facility managers. These innovations have transformed sewer inspection from a labor-intensive process into a sophisticated, technology-driven operation.

Technological Advancements Shaping the Industry

Over the years, global Sewer Camera Manufacturers have introduced a range of technologies that significantly enhance pipeline inspection. Companies like Sewer Camera Manufacturers have invested heavily in research and development, creating solutions that combine high-resolution imaging, rugged hardware, and intelligent software. These innovations allow inspection teams to identify blockages, leaks, corrosion, and structural defects quickly and accurately, without resorting to costly excavation.

High-Resolution Imaging and Optical Precision

One of the most notable trends in sewer camera technology is the adoption of high-definition and ultra-high-definition imaging. Modern cameras now provide exceptional clarity, enabling operators to detect small cracks, root intrusions, and sediment buildup. Advanced lens systems with wide-angle capabilities allow comprehensive coverage of pipeline interiors, reducing the time and effort required for inspections while improving the accuracy of diagnostics.

Enhanced Illumination Systems

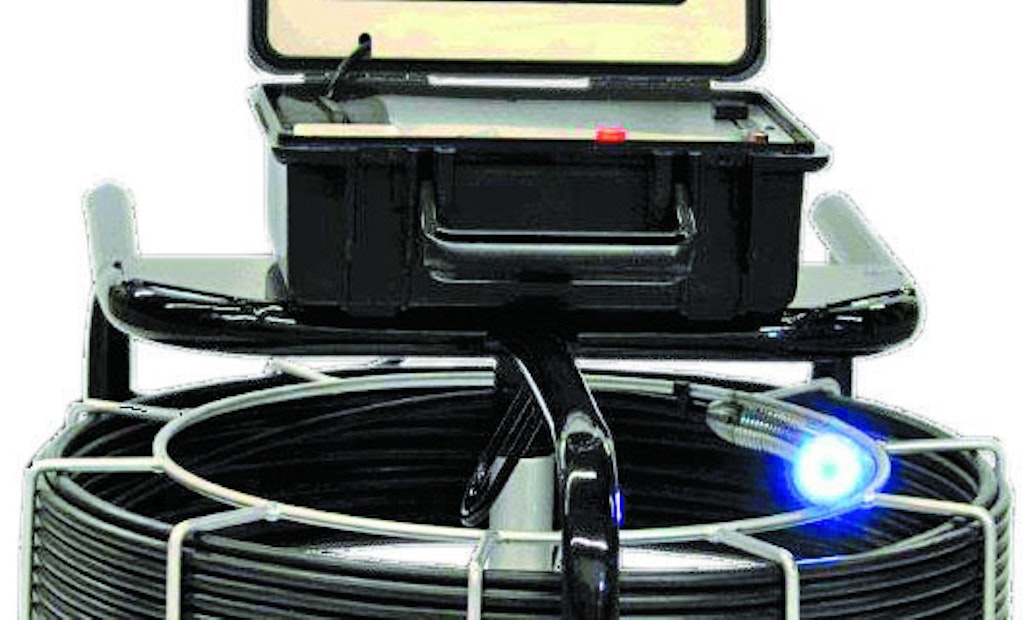

Lighting has become a critical component of sewer cameras, as underground pipelines are often dark and obstructed. Manufacturers have developed powerful LED lighting systems that deliver uniform illumination without glare. Adaptive lighting technologies automatically adjust brightness based on pipe diameter and surface conditions, ensuring consistent visibility in various environments. These innovations allow inspectors to conduct thorough assessments even in challenging conditions.

Robust Construction and Durability

Sewer inspection equipment must withstand harsh operating environments, including exposure to water, chemicals, and physical impacts. Advances in materials and design have led to more durable camera heads, featuring stainless steel housings, waterproof seals, and scratch-resistant lenses. These improvements extend the lifespan of equipment, reduce maintenance costs, and provide reliable performance over long-term usage.

Flexible Push Rods and Cable Innovation

Camera mobility is essential for reaching deep or complex pipeline networks. Innovative push rods and cables made from fiberglass and composite materials provide flexibility without compromising strength. These systems maintain signal integrity during navigation through bends and tight spaces, ensuring uninterrupted video transmission and minimizing operational disruptions.

Integration of Digital Recording and Data Management

Modern sewer cameras are no longer standalone devices. They now incorporate digital recording, annotation, and reporting functionalities, which streamline inspection workflows. Operators can capture high-quality footage, generate detailed reports, and store data for future reference. These features enhance communication with clients, support regulatory compliance, and facilitate predictive maintenance strategies.

Wireless Connectivity and Real-Time Monitoring

Wireless technology has revolutionized sewer inspections by enabling real-time video streaming to monitors, tablets, and remote locations. This connectivity allows multiple stakeholders to view inspections simultaneously, collaborate on decisions, and respond promptly to issues. Wireless systems also simplify data transfer and reduce the time required for post-inspection processing, improving overall efficiency.

Software Intelligence and AI Integration

Artificial intelligence and smart software solutions are increasingly integrated into sewer camera systems. Features such as automated defect detection, pipe measurement tools, and cloud-based data management enhance inspection accuracy and reduce human error. These intelligent systems help maintenance teams prioritize repairs, track infrastructure health, and implement proactive maintenance strategies, saving time and resources in the long run.

The Future of Sewer Camera Innovation

Global sewer camera manufacturers continue to drive technological progress in pipeline inspection. From high-resolution imaging and advanced lighting to AI-assisted software and wireless connectivity, innovations are reshaping how infrastructure maintenance is conducted. As urban networks expand and age, these trends will play a critical role in ensuring that sewer systems remain safe, functional, and sustainable, demonstrating the vital impact of continued research and development in this field.