In today’s fast-paced manufacturing and packaging industries, efficiency and accuracy are vital for maintaining competitiveness. As consumer demand for custom shapes, intricate designs, and high-quality finishes continues to grow, businesses are turning toward advanced cutting technologies to meet these expectations. Among these innovations, flatbed die cutting machines have become a cornerstone of modern production, providing unmatched precision and flexibility in a wide range of applications.

What is a Flatbed Die Cutting Machine?

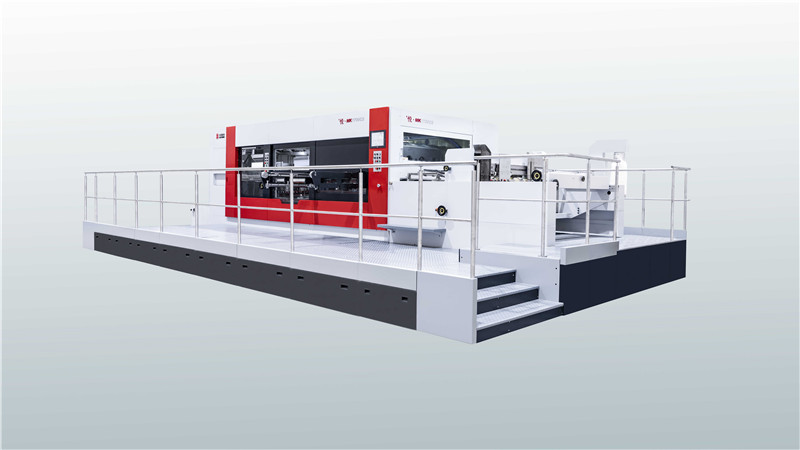

A flatbed die cutting machine is a specialized piece of equipment designed to cut, crease, emboss, and shape materials such as paperboard, corrugated cardboard, plastics, textiles, and even thin metals. Unlike rotary systems that use cylindrical dies, the flatbed design employs a flat cutting surface that presses the die directly into the material. This method allows for greater precision and the ability to handle intricate patterns and heavy-duty materials, making it an essential tool in industries ranging from packaging and printing to textiles and automotive components.

Key Advantages of Flatbed Die Cutting Machines

1. Unmatched Cutting Precision

Flatbed systems are engineered to handle detailed and complex shapes with extreme accuracy. Whether it’s fine lines, tiny perforations, or large structural cuts, the machine ensures that every design is replicated consistently. This level of precision reduces material waste and guarantees higher product quality.

2. Flexibility Across Materials

One of the most significant benefits of flatbed die cutting machines is their ability to work with diverse materials. From thick corrugated sheets to delicate specialty papers, the same machine can adapt to various production needs. This versatility makes it an invaluable investment for companies that produce packaging, promotional materials, or custom-designed products.

3. Support for Large-Format Jobs

Flatbed die cutters excel in managing large sheets and heavy materials that are often challenging for rotary cutters. This makes them ideal for large-format packaging, point-of-sale displays, and industrial components that require sturdier substrates.

4. Enhanced Efficiency and Speed

Modern flatbed machines are equipped with automated feeding, registration, and stacking systems. These features improve throughput while minimizing manual intervention, allowing manufacturers to keep up with tight deadlines without sacrificing quality.

Applications of Flatbed Die Cutting

Packaging Industry

The packaging sector is one of the largest beneficiaries of flatbed die cutting. From folding cartons and corrugated boxes to luxury packaging with intricate embossing, the technology ensures that every product stands out on the shelf.

Printing and Promotional Materials

Flatbed die cutters are widely used in printing houses for producing items such as business cards, brochures, stickers, and promotional displays. Their ability to handle complex shapes allows brands to create unique and eye-catching designs.

Automotive and Industrial Uses

In addition to consumer products, flatbed die cutting is employed in industries like automotive, where precision-cut gaskets, seals, and insulation materials are required. The ability to cut durable and non-traditional materials highlights the machine’s industrial value.

Textile and Fashion Industry

The fashion industry benefits from flatbed die cutters for producing patterns, appliqués, and fabric components. The accuracy and consistency of cuts help reduce waste and improve overall efficiency in garment production.

How Flatbed Die Cutting Stands Apart from Rotary Systems

While rotary die cutters are suitable for high-speed, continuous production, they often fall short in terms of precision and flexibility. Flatbed die cutting, on the other hand, offers:

- Greater adaptability to complex and custom designs

- The ability to cut thicker and rigid materials

- High-quality finishes for detailed and premium products

This makes flatbed systems the preferred choice when quality and versatility take precedence over sheer volume.

The Role of Automation and Digital Integration

Advancements in automation have further elevated the capabilities of flatbed die cutting machines. Features like computer-aided design (CAD) integration, automated tool changes, and real-time monitoring enhance productivity while reducing human error. Additionally, digital controls make it easier to adjust settings, ensuring quick transitions between different projects.

Sustainability and Material Optimization

As industries move toward sustainable practices, flatbed die cutting machines contribute by minimizing waste. The precision of the cuts ensures that maximum material is utilized, reducing excess scrap. Additionally, the ability to handle recycled and eco-friendly materials makes these machines compatible with green initiatives.

Choosing the Right Flatbed Die Cutting Machine

When selecting a machine, businesses should consider factors such as:

- Material compatibility: Can the system handle the substrates required for your production line?

- Cutting size and capacity: Does it support large-format jobs if needed?

- Automation features: Are there tools to improve workflow efficiency and reduce downtime?

- Durability and maintenance: Is the system built for long-term use with minimal servicing?

Investing in the right machine ensures not only better output but also long-term operational savings.

Future Trends in Flatbed Die Cutting

The future of die cutting lies in the integration of smart technology, artificial intelligence, and IoT-enabled monitoring systems. These innovations will allow machines to self-diagnose issues, optimize cutting paths, and further reduce material waste. As customization becomes a stronger market demand, flatbed die cutters will continue to evolve, bridging the gap between mass production and bespoke manufacturing.

Conclusion

Flatbed die cutting machines have revolutionized how industries approach cutting, shaping, and finishing tasks. Their ability to deliver precision, adaptability, and efficiency makes them a cornerstone of modern manufacturing processes. As industries continue to demand sustainable, high-quality, and innovative solutions, flatbed die cutting technology will remain a vital tool for driving creativity and operational success.