In modern manufacturing, precision and efficiency are paramount. Industries such as medical device production, electronics, and aerospace demand components with extremely tight tolerances and complex geometries. Traditional machining methods often struggle to meet these requirements consistently, which is why the Swiss type CNC lathe has become an essential tool for manufacturers seeking high accuracy and repeatability. Understanding its advantages can help businesses make informed decisions when investing in advanced machining solutions.

What is a Swiss Type CNC Lathe?

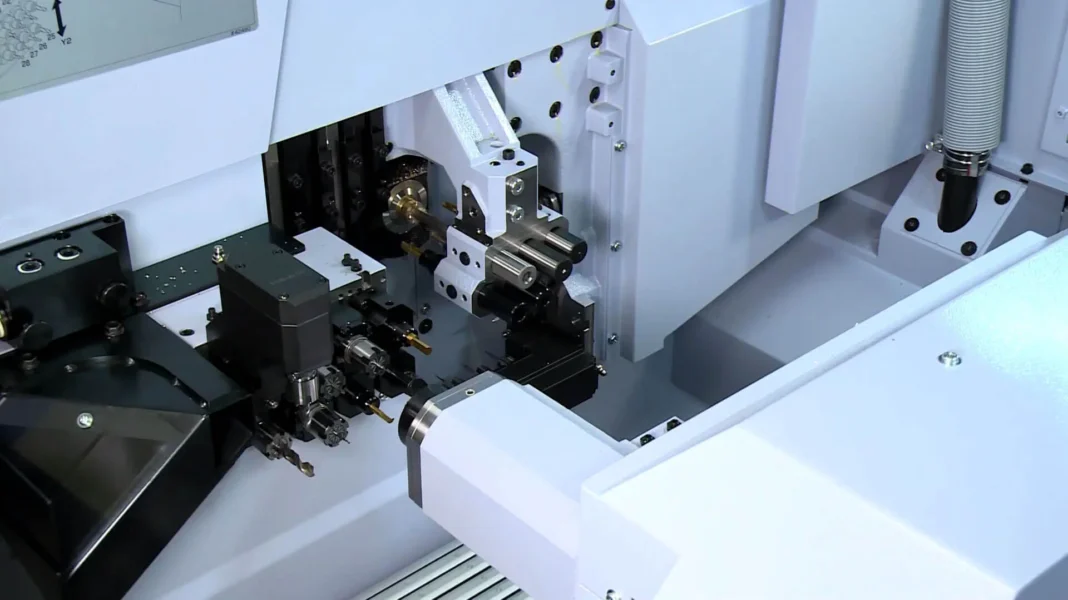

A Swiss type CNC lathe is a specialized lathe designed to produce small, intricate parts with exceptional precision. Unlike conventional lathes, which hold the workpiece stationary while the cutting tools move along it, a Swiss type lathe moves the workpiece through a guide bushing. This configuration allows the cutting tools to operate very close to the point of support, minimizing deflection and vibration. As a result, even extremely slender and long components can be machined with minimal error. This design makes Swiss lathes ideal for manufacturing screws, medical implants, watch components, and other precision parts.

Advantages of Using a Swiss Type CNC Lathe

One of the primary benefits of a Swiss type CNC lathe is its ability to deliver high precision consistently. The guide bushing support system ensures that even complex, slender parts are machined with minimal deviation. This reduces waste and improves overall efficiency in production. Additionally, these machines are capable of performing multiple operations in a single setup, such as turning, drilling, milling, and threading, which eliminates the need for multiple machines and reduces handling errors.

Another significant advantage is the machine’s versatility. Modern Swiss type CNC lathes come equipped with multiple axes, allowing for intricate geometries and complex designs that would be difficult to achieve on a standard lathe. They also accommodate a wide range of materials, from soft plastics to hardened steels, providing manufacturers with the flexibility needed for diverse applications.

Investing in a high-quality swiss type cnc lathe can enhance production efficiency significantly. By combining precision, speed, and automation, manufacturers can achieve higher output without compromising quality. The reduction in manual intervention not only saves time but also minimizes human error, ensuring that parts consistently meet strict tolerance requirements.

Impact on Small-Batch and High-Mix Production

Swiss type CNC lathes are particularly valuable for small-batch and high-mix production environments. Unlike traditional lathes that require extensive setup time, these machines can switch between different part designs quickly due to advanced CNC programming. This adaptability allows manufacturers to respond rapidly to changing customer demands while maintaining consistent quality.

Additionally, the automation features of Swiss lathes reduce labor costs and improve operational efficiency. Once the machine is programmed and set up, it can run unattended for extended periods, producing high volumes of parts with minimal supervision. This combination of flexibility and productivity makes Swiss type CNC lathes a preferred choice for industries where precision and turnaround time are critical.

Maintenance and Longevity Benefits

Another important benefit is the durability and longevity of Swiss type CNC lathes. Built with high-quality components and designed for continuous operation, these machines require less frequent maintenance compared to conventional lathes. Proper care and scheduled maintenance ensure that the lathe continues to deliver consistent precision over many years. This long-term reliability translates into lower total cost of ownership, making it a smart investment for precision-focused manufacturers.

Conclusion

The Swiss type CNC lathe stands out as a high-precision, versatile, and efficient solution for modern manufacturing. Its unique design allows for the production of intricate and slender parts with minimal error, while its automation and multi-axis capabilities enhance productivity and reduce manual intervention. Whether for small-batch production or high-mix operations, this machine offers tangible benefits that improve both quality and efficiency. For manufacturers seeking precision, consistency, and long-term value, incorporating a Swiss type CNC lathe into their production process is a strategic choice that delivers measurable results.