Choosing the right Swiss lathe manufacturer requires more than just evaluating machine specifications and price. Certifications and adherence to industry standards are vital indicators of quality, reliability, and long-term performance. These credentials help ensure that the equipment you invest in meets stringent requirements for precision, safety, and durability.

Understanding the Importance of Certifications

Certifications are official recognitions that a manufacturer complies with internationally accepted quality and safety standards. For Swiss lathe manufacturers, these certifications demonstrate that the machines are designed, built, and tested according to rigorous procedures. They provide buyers with confidence that the equipment will deliver consistent performance and reduce the risk of operational issues.

Common Industry Standards

Several certifications and standards are particularly relevant when assessing Swiss lathe manufacturers. ISO 9001 is widely regarded as a benchmark for quality management systems, ensuring that manufacturing processes are standardized and consistently monitored. CE certification indicates compliance with European safety, health, and environmental regulations. Additionally, some manufacturers may hold industry-specific approvals, such as for medical or aerospace component production, which guarantee that machines meet specialized requirements.

Verifying Manufacturer Credentials

A reliable swiss lathe manufacturers will openly provide information about their certifications and standards. When evaluating potential suppliers, request documentation and inquire about the scope of their certifications. Confirming these credentials helps verify that the manufacturer maintains quality assurance, safety protocols, and environmentally responsible practices throughout the production process.

Assessing Quality Assurance Processes

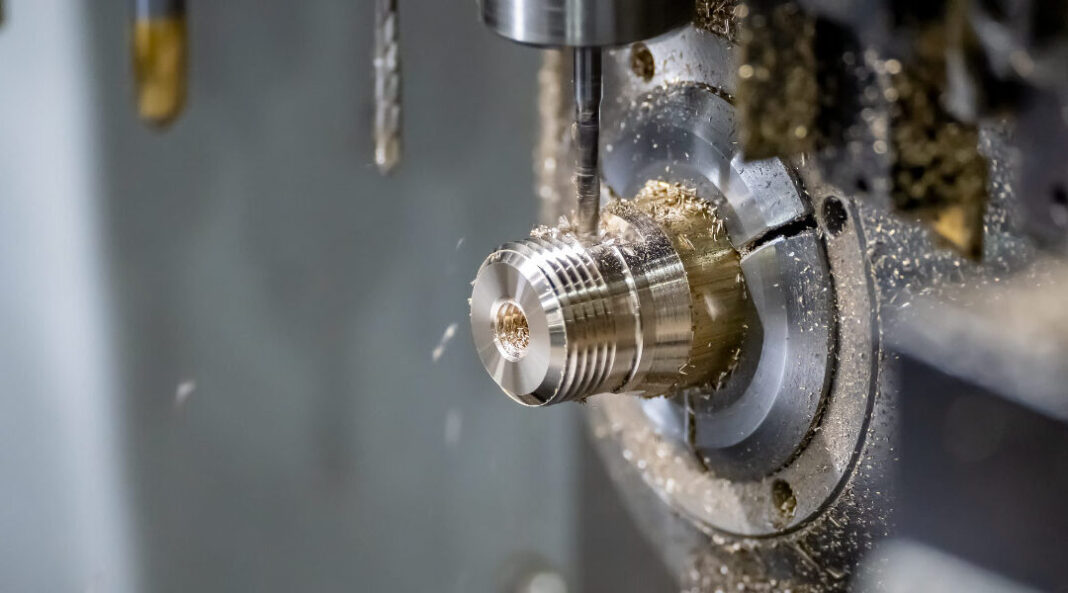

Certifications are only meaningful when supported by robust internal quality control systems. Swiss lathe manufacturers typically implement multiple inspection stages, including precision measurements, spindle alignment checks, and performance testing. High-quality manufacturers also employ automated verification systems and maintain detailed production records to ensure that every machine meets its intended specifications.

Safety Standards and Operator Protection

Safety is another crucial consideration. Swiss lathes involve high-speed operations, rotating components, and complex tooling, making adherence to safety standards essential. Certified manufacturers design machines with features such as protective enclosures, emergency stop mechanisms, and fail-safe systems. Compliance with safety certifications not only protects operators but also helps prevent costly accidents and equipment damage.

Environmental and Sustainability Standards

Sustainability is increasingly important in modern manufacturing. Many certified Swiss lathe manufacturers follow standards related to energy efficiency, waste reduction, and environmentally friendly materials. These practices minimize environmental impact while reducing operational costs, reflecting the manufacturer’s commitment to responsible production.

Continuous Improvement and Audits

Certifications often require periodic audits and adherence to continuous improvement practices. Manufacturers who actively participate in audits and update their processes demonstrate a commitment to maintaining high-quality standards. This ensures that machines remain reliable, precise, and competitive over time.

Evaluating Additional Credentials

Beyond the most common certifications, consider any additional credentials that may add value to your investment. These might include industry-specific standards, awards for innovation, or partnerships with technology providers. Such recognitions indicate a manufacturer’s dedication to quality, precision, and customer satisfaction.

Conclusion

When selecting Swiss lathe manufacturers, certifications and adherence to recognized standards provide a crucial benchmark for evaluating quality, safety, and reliability. ISO, CE, and other industry-specific approvals reflect a manufacturer’s commitment to excellence, while robust quality control processes and continuous improvement practices ensure consistent performance. By prioritizing certified manufacturers, businesses can make informed decisions, safeguard their investments, and achieve long-term success in precision manufacturing.